Contact Us Today For Softwood Chips: 03 5272 2966

Geelong's Prime Softwood Woodchip Manufacturer And Exporter

Softwood Plantation Exporters (SPE) is Victoria’s leading provider of softwood chips.

We produce chips with high pulp yield and low bark content, which helps us produce less waste. Our chips feature high burst and tear strength.

In 2011, we were named Regional Exporter of the Year, so you can trust our products come highly recommended.

Slide title

Write your caption hereButton

Exceptional Softwood Chips

Pioneer for Two Decades

Chip exported through SPE is predominantly Pinus Radiata with current volume consisting of 50% from sawmill chip and 50% chip produced from forest thinning

The uniformly high quality Radiata chip makes the product an ideal feedstock for a variety of uses. Traditional end use is bleached kraft pulp and thermal mechanical pulp.

Leading Product Quality

Low bark content assists in achieving high pulp yield with little waste or pulp discolouration.

The low bark content reduces the ash output when used as feedstock for Bioenergy.

Pinus Radiata chip used in bleached and un-bleached Kraft pulp lines provides high burst and tear strength. High pulp brightness is also a characteristic.

Overall, the high proportion of sawmill chip combined with average chip age provides for good pulp characteristics and yield.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Learn More About Our Products

Softwood Plantation Exporters (SPE) is an Australian owned Company, located in Victoria, formed to process and ship softwood woodchip for export sale. SPE is a partnership between Hancock Victorian Plantations (HVP), and Associated Kiln Driers (AKD Softwoods).

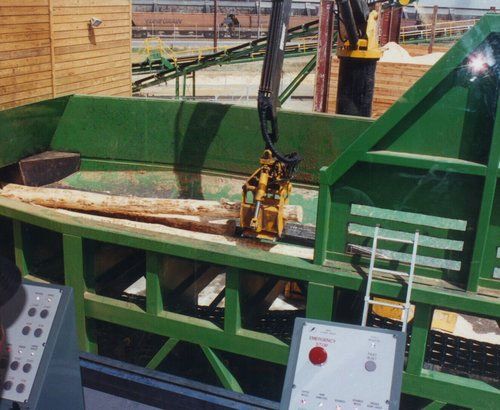

The Chipmill comprises a 125 ft. radial crane & drum debarker with associated screening, rechipping and conveying systems. Maximum chip mill capacity is 450K - 500K green metric tonnes (GMT) pa. Shipments are guaranteed to meet customers’ exacting chip specifications.

Address

P.O. Box 7041, Geelong West,

VIC 3218

Contact Information

Hours Of Operation

- Mon - Fri

- -

- Sat - Sun

- Closed